I mentioned before that I had gotten a sensor board from Charles. I had one board, which I intend to mount on TinyBike. However, I also want to put them on chipikart, which has two motors. Clearly, more sensors are needed, so I ordered some boards from my favorite purple board fab.

And two weeks later, they arrived! Solder party time!

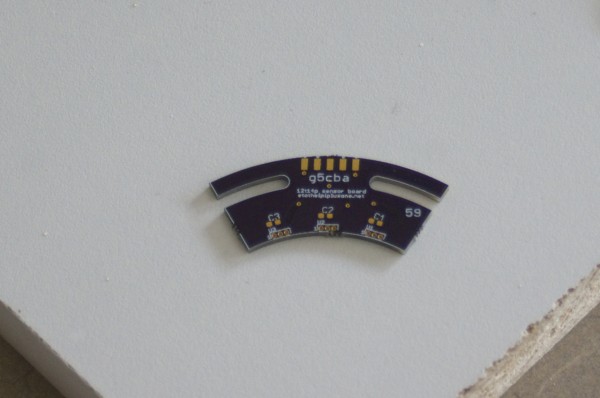

A short time later, sensors! My three boards next to the MIT original®. Now to print some mounts and then Wait a minute. I dont have motors yet.